Introduction

Design and construction of foundation system requires adequate and detailed knowledge of the ground conditions. Improper foundation design can lead to project delays, failures and cost over-run. Rapid development and technological innovation in wind energy sector leads to increase in the size of wind turbine. For large size wind turbines design of foundation systems have become very critical and it’s important to have safe operation during its service life. Reliability of foundation design depend on the accuracy of measurement of foundation soil properties through proper field and laboratory testing. The problem becomes more complex due to the non-availability of land having required bearing capacity. Considering the above criteria, it is highly essential to carryout site specific soil investigation and foundation design.

Purpose of Site Investigation

A site investigation program is necessary to provide information for design, construction, and environmental assessment. The purposes of a soil investigation are:

1. To evaluate the general suitability of the site for the proposed project.

2. To enable an adequate and economical design of the foundation system.

3. To obtain physical and mechanical properties of soil for design and construction.

4. To obtain groundwater conditions.

5. To disclose and make provisions for difficulties that may arise during construction.

6. To determine suitability of materials for construction.

Considering the variability of the soil parameters and uncertainty associated with its measurement, it is necessary to measure the properties at each wind turbine location to increase the reliability of the soil investigation report, based on which the entire design is performed.

Example

The approach to be adopted for a particular site investigation, its extent and the techniques used will depend upon the site-specific circumstances, the experience and judgement of the engineer.

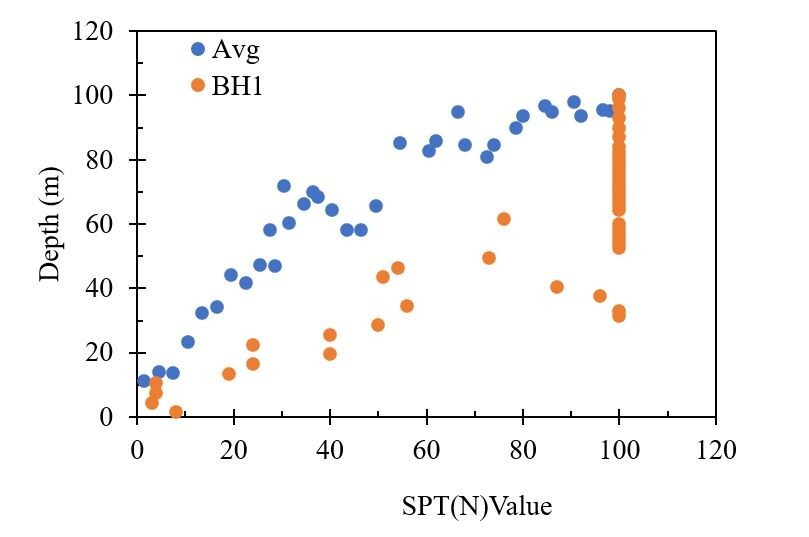

In principle, each WTG location must be investigated, if construction is to be safe and economical. Large variation in the soil properties can be observed in a proposed wind farm location as shown in Fig. 1. The design engineer often tends to use conservative soil parameters which can be non-economical. When average soil parameters are selected for the design, it can lead to over prediction of soil properties and may lead to failure or serviceability issue at some location. To achieve the safe and economical operation of the wind turbine it is proposed to carryout site specific soil investigation and foundation design for respective wind turbine.

Advantages of Site-Specific Design

- Lesser turn-around time

- Long term cost benefit

- Higher reliability of foundation system

- Lesser maintenance during service life

- Safe operation of the wind turbine

References

1. BS 5930 (2015) Code of practice for site investigations.

2. EN 1997-1 (2004) Geotechnical design- Part-1: General Rules.

3. EN 61400-1 (2005) Wind turbine generator systems. Part 1: Safety requirements.

4. IS 1892 (1979) Code for practice for sub surface investigation for foundations.

5. IEC 61400-1 (2019) Wind energy generation systems – Part 1: Design requirements.