NeXHS is actively involved in the rehabilitation and retrofitting of wind turbines. NeXHS utilises its technical expertise in the design and construction of wind turbines to identify the cause of damage or deterioration of the structure and how to increase its service life.

A detailed evaluation and site investigation is carried out to identify and understand the root cause of the problem.Reports from NDT testing, Concrete Core analysis, Borescopy etc., were evaluated in detail before providing the solution.

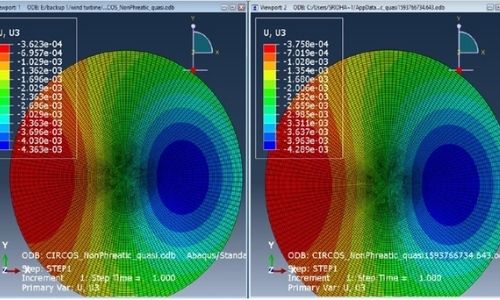

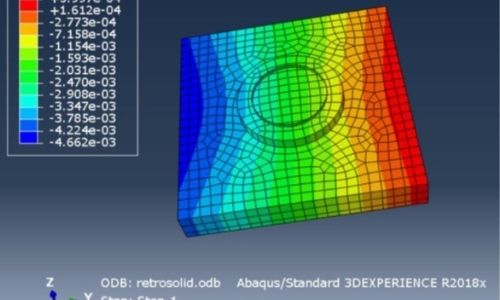

The structure is also analysed using the Finite Element Method to understand the damage and to propose an effective and optimum solution.

Some case studies of retrofitting work are mentioned below;

Case I

Project overview:

• Delay in the concreting of the slab and pedestal.

Conceptualisation of the Problem:

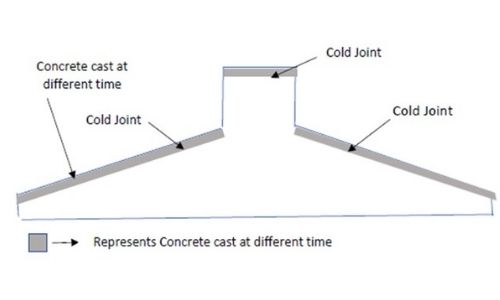

Cracks or cold joints were formed at the slab and pedestal region of the wind turbine foundation because the concrete was cast at different times.Analysis was carried out for the reduced properties of concrete by reducing the stiffness of the concrete.

Based on the results from the analysis the solutions were provided for the retrofitting.

Solution Provided by NeXHS:

The methodology used for retrofitting is Jacketing of the existing slab portionwithout affecting the normal operation of the turbine during its design life.

Case II

Project Overview:

The square foundation of the WTG tower was reported to have vibration which resulted in the loss of bond between the region of the embedded can and the underlying concrete area. NDT tests and bosrescopy were performed to evaluate the strength of the concrete.

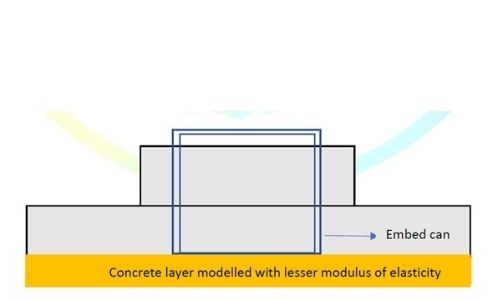

Conceptualisation of the Problem:

Minor cracks were observed at the bottom portion,and it was inferred that the concrete at the bottom region of the foundation has lost contact with the embed can.

Solution Provided by NeXHS:

To match with the stiffness criteria,introduction of studs along the circumference of the embedded can was proposed. Further, grouting was donein multiple places to increase the bonding between the existing concrete.